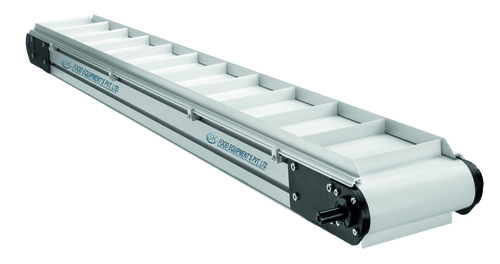

Sidewall Cleated Belt Conveyor

Price 125000 INR/ Set

Sidewall Cleated Belt Conveyor Specification

- Surface Finish

- Powder Coated or Galvanized

- Belt Type

- Corrugated Sidewall Cleated Belt

- Thickness

- Belt thickness 5-12 mm

- Features

- High Incline, Space Saving, Low Maintenance, High Efficiency

- Power Source

- Electric

- Material

- Rubber, PVC, or PU Belt with Steel Frame

- Type

- Sidewall Cleated Belt Conveyor

- Structure

- Mild Steel or Stainless Steel Frame

- Belt Conveyor

- Yes

- Roller Conveyor

- No

- Vertical Conveyor

- Yes, supports steep inclines & vertical lift

- Pneumatic Conveyor

- No

- Resistant Feature

- Oil & Heat Resistant, Anti-Corrosive, Flame Retardant

- Load Capacity

- Customizable up to 200 kg/m

- Voltage

- 220 V / 380 V (as required)

- Power

- 0.75 kW to 7.5 kW

- Speed

- 0.5 to 2.5 m/s (adjustable)

- Usage & Applications

- Bulk Material Handling, Sand, Coal, Grain, Fertilizer, Food Processing

- Cleat Height

- 30 mm to 80 mm

- Customization

- Available as per application requirement

- Noise Level

- <70 dB(A)

- Control Panel

- Optional, with VFD for speed control

- Operating Temperature

- -10°C to 60°C

- Conveyor Width

- 200 mm to 1000 mm

- Maintenance

- Low, easy to clean and service

- Conveyor Length

- Customizable up to 30 meters

- Drive Type

- Direct/Geared Motor

- Mounting Type

- Floor mounted or portable

Sidewall Cleated Belt Conveyor Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 5 Sets, , Per Month

- Delivery Time

- 4 Days

About Sidewall Cleated Belt Conveyor

Advanced Applications and Versatile Use: Sidewall Cleated Belt Conveyor

Sidewall Cleated Belt Conveyors are extensively used as high-efficiency solutions for bulk material transfer in various industries. Classified as heavy-duty equipment, they are ideal for plant applications such as food processing, grain handling, sand distribution, fertilizer conveying, and coal movement. These conveyors support steep incline or vertical transfer, making them indispensable in factories with limited floor space or unique process requirements. Their robust build and tailored configurations ensure they meet specific plant and application demands, enhancing productivity.

Samples, Certifications, and Hassle-Free Dispatch

Sample Sidewall Cleated Belt Conveyors are available at a special sale price, offering customers the chance to assess performance before purchase. Products are certified to meet stringent quality standards, ensuring reliability and safety. Our sample policy allows for easy procurement, with prompt dispatched goods and minimal freight charges. Whether you are specifying new project requirements or upgrading existing systems, our streamlined process assures swift delivery and complete satisfaction.

FAQs of Sidewall Cleated Belt Conveyor:

Q: How does the Sidewall Cleated Belt Conveyor benefit material handling processes?

A: The Sidewall Cleated Belt Conveyor offers stellar efficiency in moving bulk materials steeply or vertically, saving space and reducing manual labor. Its customizable design and robust construction enable seamless handling of various materials, enhancing overall operational productivity.Q: What types of materials can this conveyor transport?

A: This conveyor efficiently handles a wide range of bulk materials, including sand, coal, grain, fertilizer, and items processed in the food industry. It is compatible with oil and heat-resistant, anti-corrosive, and flame-retardant belt types, ensuring safe and reliable transport.Q: Where can the Sidewall Cleated Belt Conveyor be installed?

A: It can be floor-mounted for fixed installations or set up as a portable solution, making it suitable for factories, plants, and industrial sites requiring high-incline or vertical material transfer.Q: What is the process for customizing the conveyor to specific requirements?

A: Customers provide details such as desired conveyor length, width, cleat height, and load capacity. The manufacturer then designs and fabricates the conveyor to match the exact application and operational requirements, ensuring optimal integration.Q: When should the optional control panel with VFD be used?

A: The optional control panel with VFD (Variable Frequency Drive) should be used when there is a need for adjustable speed control, allowing precise tuning for different materials and process flow demands.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Belt Conveyor Category

PU Belt Conveyor

Price 125000 INR / Set

Minimum Order Quantity : 1 Set

Structure : Other, Mild Steel Frame

Type : Other, PU Belt Conveyor

Pneumatic Conveyor : Other, No

Speed : Up to 30 m/min

Stainless Steel Screw Conveyor

Price 125000 INR / Set

Minimum Order Quantity : 1 Set

Structure : Other, Tubular or trough (Utype) structure, modular design

Type : Screw Conveyor

Pneumatic Conveyor : Other, Not applicable (mechanical screw type)

Speed : 1260 RPM (adjustable)

Vertical Mixer

Price 165000 INR / Set

Minimum Order Quantity : 1 Set

Structure : Other, Heavyduty steel frame

Type : Other, Vertical Mixer

Pneumatic Conveyor : Other, Optional pneumatic loading system

Speed : Adjustable 30 to 60 RPM

Power Belt Conveyors

Price 125000 INR / Set

Minimum Order Quantity : 1 Set

Structure : Belt

Type : Belt Conveyor

|

S. K. Food Equipments Pvt Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry