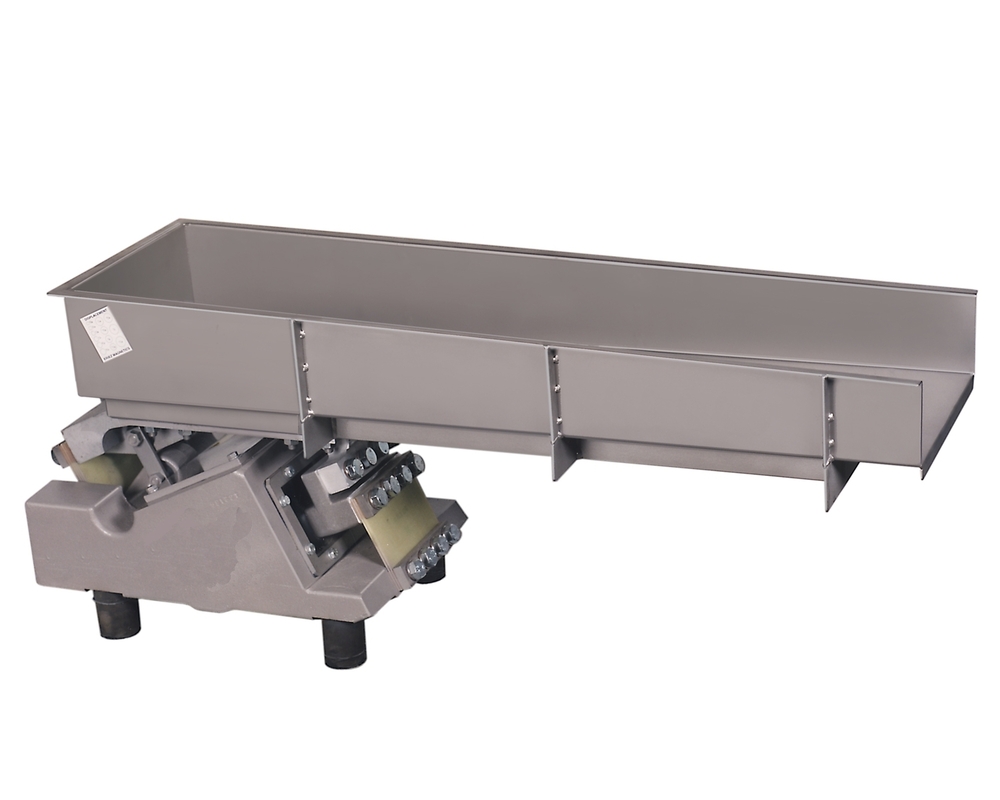

Meal Mixer

Price 125000 INR/ Set

Meal Mixer Specification

- Type

- Meal Mixer

- Material

- Stainless Steel

- Capacity

- 100 Kg/Batch

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 220 V

- Frequency (MHz)

- 50 Hz

- Preheating Plate Size

- 500 mm x 400 mm

- Cutting Thickness

- Adjustable (up to 10 mm)

- Size

- Standard

- Width

- 800 mm

- Weight

- 120 kg

- Dimension (L*W*H)

- 1200 mm x 800 mm x 1200 mm

- Mixing Speed

- 35 RPM

- Operation Mode

- Batch

- Noise Level

- Less than 70 dB

- Application

- Commercial Canteens, Food Processing Plants

- Motor Power

- 2 HP

- Bowl Material

- SS304 Grade

- Finishing

- Matt/Glossy

- Safety Features

- Overload Protection, Emergency Stop

- Power Source

- Electric

Meal Mixer Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 5 Sets Per Month

- Delivery Time

- 2-3 Week

About Meal Mixer

Specification

- AC Motor: 2.0 HP (Make C.G)

- Capacity: 50 kg/ hour

- MOC: Stainless steel

- Electric supply: 415 V 50 Hz 4 wire

- Contact parts are food grade

- Standard parts ensure long life

Specification

|

Country of Origin |

Made in India |

|

Capacity |

100 KG/Hour |

|

Usage/Application |

Mixing |

|

Model Name/Number |

SKFE-022 |

|

Automation Grade |

Automatic |

|

Voltage |

415 V |

|

Frequency |

50 Hz |

|

Shape |

U-Type |

|

Material |

Stainless Steel 304 |

High-Capacity, Efficient Meal Mixing

Designed for demanding environments like food processing plants, this Meal Mixer supports batch operations up to 100 kg, maximizing productivity. The 2 HP electric motor delivers consistent 35 RPM mixing speed, ensuring thorough blending for large volumes. Its semi-automatic operation streamlines workflow while maintaining operator control.

Durable Construction and Safety Assurance

Manufactured with SS304-grade stainless steel, this mixer withstands rigorous daily use. Critical safety features such as overload protection and an emergency stop protect both operators and equipment, prioritizing workplace safety. With both matt and glossy finishes available, the mixer complements any commercial setting.

Versatile Features for Diverse Applications

The Meal Mixer serves multiple roles as an exporter, manufacturer, service provider, and supplier in India. Its preheating plate, adjustable cutting thickness, and user-friendly batch operation bring flexibility to food preparation processes. Operating quietly and reliably on standard 220 V/50 Hz power, it offers smooth integration into various workflows.

FAQ's of Meal Mixer:

Q: How does the Meal Mixer ensure operator safety during usage?

A: The mixer is equipped with overload protection and an emergency stop feature, minimizing risks associated with equipment misuse or unexpected malfunctions. These safety mechanisms are designed to safeguard both users and the machinery during operation.Q: What is the maximum capacity and batch size for the Meal Mixer?

A: This Meal Mixer accommodates up to 100 kilograms per batch, making it suitable for high-volume food processing in commercial canteens and large kitchens.Q: When is it recommended to use the Meal Mixer in food preparation?

A: The mixer is ideal for large-scale meal preparation whenever consistent mixing, efficient batching, and reliable safety are required-particularly in commercial canteens or food processing plants handling bulk ingredients.Q: Where is the Meal Mixer typically installed and used?

A: It is commonly deployed in industrial kitchens, commercial canteens, and food processing facilities, benefiting businesses in India as both an exporter and supplier.Q: What process does the Meal Mixer follow for optimal mixing?

A: Ingredients are added to the SS304 stainless steel bowl, and the mixer, operating at 35 RPM, blends them thoroughly in batch mode. The semi-automatic controls allow precise operation while maintaining efficiency.Q: How does the adjustable cutting thickness enhance usage?

A: With variable cutting thickness up to 10 mm, the mixer adapts to recipes requiring different textures and ingredient sizes, improving its versatility across food processing applications.Q: What are the benefits of its stainless steel construction and noise reduction?

A: SS304-grade stainless steel assures hygiene, corrosion resistance, and durability, while noise levels below 70 dB contribute to a quieter working environment, enhancing user comfort during extended operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Snacks & Food Processing Machine Category

Twin Screw Corn Puff Snacks Food Extruder

Price 1050000 INR / Set

Minimum Order Quantity : 1 , , Set

Computerized : Yes

Type : Twin Screw Corn Puff Snacks Food Extruder

Voltage : 380V

Automatic Grade : Automatic

Vibratory Feeders

Price 65000 INR / Set

Minimum Order Quantity : 01 Set

Computerized : No

Type : Vibratory Feeder

Voltage : 220440 V

Automatic Grade : Automatic

Mad Angle Cutter

Price 175000 INR / Set

Minimum Order Quantity : 1 Set

Computerized : No

Type : Mad Angle Cutter

Voltage : 220V

Automatic Grade : SemiAutomatic

Oven Tray Dryer Machine

Price 250000 INR / Set

Minimum Order Quantity : 01 , , Set

Computerized : No

Type : Oven Tray Dryer Machine

Voltage : 220240 V

Automatic Grade : SemiAutomatic

|

S. K. Food Equipments Pvt Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry