Twin Screw Corn Puff Snacks Food Extruder

Price 1050000 INR/ Set

Twin Screw Corn Puff Snacks Food Extruder Specification

- Type

- Twin Screw Corn Puff Snacks Food Extruder

- Material

- Stainless Steel

- Capacity

- 100-200 kg/h

- Computerized

- Yes

- Automatic Grade

- Automatic

- Voltage

- 380V

- Frequency (MHz)

- 50Hz

- Cutting Thickness

- Adjustable

- Size

- Medium Scale Plant Equipment

- Weight

- 1500 kg

- Dimension (L*W*H)

- 2600 mm x 900 mm x 1900 mm

- Finished Product Shape

- Round, Ring, Star, Core-Filled, Ball

- Operator Required

- 1-2 persons

- Raw Material

- Corn Grits, Rice Meal, Wheat Flour, Other Grains

- Production Line Application

- Snacks Food, Breakfast Cereals

- Heating Method

- Electric

- Feeding Type

- Screw Feeding

- Condition

- New

- Control System

- PLC Control Panel

- Cooling System

- Water Cooling

- Extruder Screw Material

- Alloy Steel

- Main Motor Power

- 37 kW

Twin Screw Corn Puff Snacks Food Extruder Trade Information

- Minimum Order Quantity

- 1 , , Set

- Supply Ability

- 5 Sets Per Month

- Delivery Time

- 2-3 Week

About Twin Screw Corn Puff Snacks Food Extruder

Specification

| Material To Be Extruded | Corn Puff Snacks |

| Capacity | 100-120 KG/Hour |

| Power Consumption | 20 kW |

| Voltage | 415 V 50 Hz 4 Wire |

| Automation Grade | Automatic |

| Phase | Three Phase |

| Power Source | Electric |

| Material | Stainless Steel |

Technical Specification:-

- AC Main Motor : 20.0 kW

- AC Motor for Feeding : 0.75 kW

- AC Motor for Cutting : 0.75 kW

- Heating Aliment : 0.50 kW (03 Nos.)

- Production Capacity : 100 to 120 KG/Hr.

- Electric Supply : 415 V 50 Hz 4 Wire

Efficient Production with Advanced Automation

The extruder employs a PLC control panel and computerized automation, enabling precise regulation over temperature, feed rate, and cutting thickness. Operators benefit from an intuitive interface and reduced manual intervention, making consistent, high-quality snack production achievable with just 1-2 personnel on-site.

Versatile Shaping and Material Support

Accommodating a diverse selection of raw ingredients-from corn grits to other grains-this machine crafts snacks in innovative shapes such as balls, rings, stars, and core-filled puffs. Its adjustable cutters and alloy steel screws allow quick adaptation to changing product designs and market trends.

Durability and Hygiene Guaranteed

Constructed from stainless steel and equipped with a robust water cooling system, this extruder withstands rigorous daily operation while maintaining sanitary processing standards. The use of alloy steel screws enhances longevity and performance, ensuring minimal downtime and low maintenance requirements.

FAQ's of Twin Screw Corn Puff Snacks Food Extruder:

Q: How does the extruder process different snack shapes?

A: The Twin Screw Corn Puff Snacks Food Extruder uses interchangeable molds and adjustable cutters to form a range of shapes such as round, ring, star, core-filled, and ball snacks. Operators can switch between molds and adjust cutting thickness easily to produce various designs based on market demand.Q: What types of raw materials can be used with this machine?

A: This extruder supports multiple grains including corn grits, rice meal, wheat flour, and other suitable grains. Users can select raw materials according to their desired finished product texture and taste, providing flexibility for developing new flavors and mixes.Q: When should the cooling system be activated during production?

A: The water cooling system is automatically engaged during extrusion cycles to regulate the temperature of the machine components, protecting them from overheating and ensuring consistent puff quality throughout production runs.Q: Where is this extruder best utilized?

A: Designed for medium-scale factories, food processing plants, and snack manufacturers, this extruder is an ideal choice for those in India seeking to automate and expand their snack or breakfast cereal production capabilities efficiently.Q: What benefits does PLC control offer to operators?

A: PLC control allows for precise adjustment of operational parameters, automation of processes, and real-time monitoring of production data. This leads to improved product consistency, minimal operator error, and enhanced energy efficiency.Q: How many operators are needed to run the machine efficiently?

A: Only 1-2 trained individuals are required to manage operation, monitoring, and routine maintenance tasks thanks to its automated and user-friendly system.Q: Can the finished product thickness be adjusted?

A: Yes, the cutting thickness of snacks produced by the extruder is adjustable. Operators can modify settings to match desired cell structure and texture, catering to specific market or customer preferences.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Snacks & Food Processing Machine Category

Rectangle Batch Fryer

Price 175000 INR / Set

Minimum Order Quantity : 1 Set

Material : Stainless Steel

Weight : 450 kg

Frequency (MHz) : 5060 Hz

Size : Customizable

Bingo Made Angle Making Machine

Price 175000 INR / Set

Minimum Order Quantity : 1 Set

Material : Mild Steel

Weight : 1800 kg

Frequency (MHz) : 50

Size : Standard

Puff Snacks Making Machine

Price 350000 INR / Set

Minimum Order Quantity : 1 Set

Material : Stainless Steel

Weight : 1500 Kg

Frequency (MHz) : 50 Hz

Size : Large

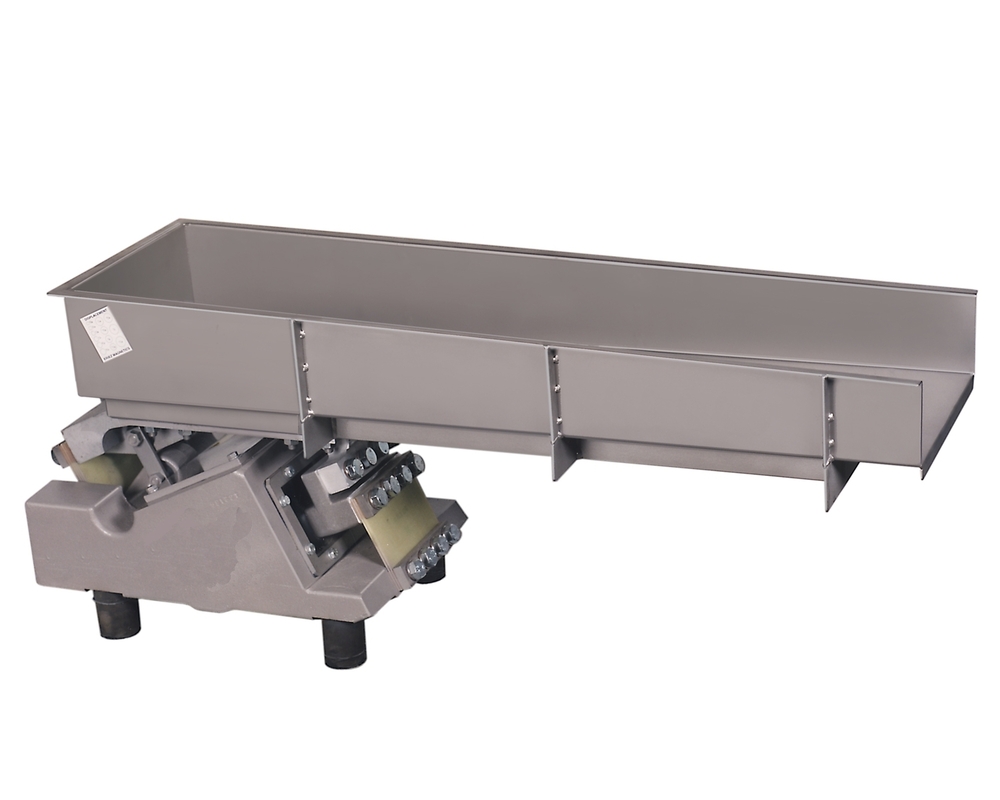

Vibratory Feeders

Price 65000 INR / Set

Minimum Order Quantity : 01 Set

Material : Mild Steel

Weight : Approx. 150500 kg

Frequency (MHz) : 50 Hz

Size : Customizable as per requirement

|

S. K. Food Equipments Pvt Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry