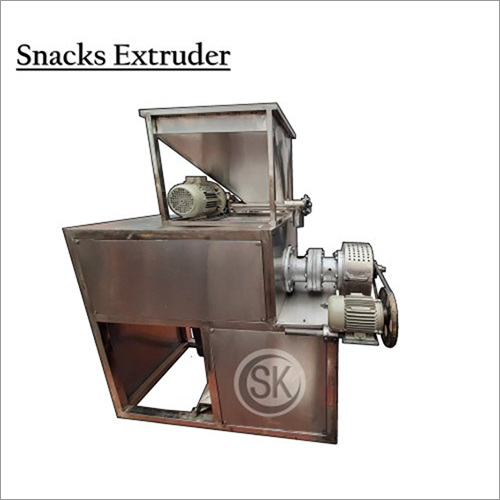

Corn Snacks Machine

Price 350000 INR/ Set

Corn Snacks Machine Specification

- Type

- Corn Snacks Machine

- Material

- Stainless Steel

- Capacity

- 100-150 kg/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Voltage

- 220-380 V

- Frequency (MHz)

- 50 Hz

- Preheating Plate Size

- 500x500 mm

- Cutting Thickness

- Adjustable

- Size

- Large

- Width

- 950 mm

- Weight

- 250 kg

- Dimension (L*W*H)

- 1800x950x1200 mm

- Operation Mode

- Continuous

- Finish Type

- Mirror Polished

- Application

- Corn Snacks, Puff Corn, Cheese Balls, Kurkure, Nik Naks

- Feeding Type

- Screw Feeding

- Noise Level

- < 70 dB

- Power

- 18.5 kW

- Color

- Silver

- Production Line

- Fully Automatic

- Cooling System

- Air Cooling

- Control Panel

- Touch Screen PLC

Corn Snacks Machine Trade Information

- Minimum Order Quantity

- 1 , , Set

- Supply Ability

- 5 Sets Per Month

- Delivery Time

- 2-3 Week

About Corn Snacks Machine

Specification

| Country of Origin | Made in India |

| Machine Type | Automatic |

| Capacity | 90-100 KG |

| Power Consumption | 20 kW |

| Material To Be Extruded | Corn & Rice |

| Brand | SK |

| Design | SKFE-031 |

| Gear Motor | 1.0 HP |

| Main Motor Power | 25.0 HP |

| Material Grade | Food Grade |

| Production Capacity | 90-100 KG/Hour |

| Usage/Application | used for extruder corn puff snacks items |

| Snacks Type | Corn Puff, Rings |

| Power | 20 kW |

| Phase | 415 V 50 Hz 4 Wire |

Technical Specification:-

- AC Motor : 25.0 HP(Make:CG/Havells)

- AC Motor for feed control : 1.0 HP(Make:CG)

- AC Motor for vary cutter speed : 1.0 HP(Make:CG)

- Capacity : 90-100 KG/Hour

- MOC : Stainless Steel

- Electric Supply : 415 V 50 Hz 4 Wire

Advanced Automation for Maximum Efficiency

With its fully automatic operation, computerized PLC control panel, and continuous production mode, this machine offers minimal manual intervention. The integrated touch screen interface gives operators intuitive control, ensuring quick and precise adjustments to settings such as cutting thickness and temperature.

Robust Construction and Modern Design

Manufactured from high-grade stainless steel and finished with a mirror polish, the machine is designed for durability, hygiene, and easy cleaning. Its large size, substantial weight, and industrial-grade design make it well-suited for high-demand commercial operations.

Versatility Across Snacks and Applications

Capable of producing a wide spectrum of popular snacks, including cheese balls, Kurkure, and Nik Naks, this machine is a versatile solution for food businesses aiming to diversify their snack offerings. Its large preheating plate and adjustable cutting system allow for a variety of shapes and sizes.

FAQs of Corn Snacks Machine:

Q: How does the Corn Snacks Machine operate?

A: The machine runs on a computerized control system with a touch screen PLC interface. Raw materials are screw-fed into the processing chamber, where automatic heating, cooking, shaping, and cutting occur in a continuous cycle. Adjustments to cutting thickness and production parameters can be made in real-time.Q: What types of snacks can be produced with this machine?

A: This machine is designed for making a broad range of puffed corn snacks, including puff corn, cheese balls, Kurkure, and Nik Naks. Its versatility allows manufacturers to craft snacks of varying shapes and sizes according to market demand.Q: When is it ideal to use this fully automatic production line?

A: This production line is best suited for large-scale snack manufacturing where consistent quality, high output (100150 kg/hr), and minimal manual intervention are priorities. Its ideal for commercial food factories and industrial kitchens.Q: Where is the Corn Snacks Machine typically installed?

A: The machine is commonly installed in snack production facilities, food processing plants, or commercial kitchens that specialize in large-volume snack preparation. Its substantial dimensions require adequate floor space and access to suitable electrical supply (220380 V).Q: What processes are involved in snack production with this machine?

A: Production involves screw feeding of raw ingredients, automated mixing and preheating (on a 500x500 mm plate), extrusion or shaping, adjustable cutting, and air cooling. The entire process is continuous, resulting in uniform and high-quality snacks.Q: What are the key benefits of using this Corn Snacks Machine?

A: Benefits include high efficiency, consistent product quality, reduced labor costs, precise control over snack characteristics, low noise operation (<70 dB), energy efficiency, and hygienic stainless steel construction thats easy to maintain.Q: How do I ensure optimal usage and maintenance of the machine?

A: Regularly clean all contact surfaces, check screw feeder operation, monitor air cooling functionality, and follow manufacturer guidelines for PLC system updates. Scheduled maintenance ensures longevity and consistent production output.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Snacks & Food Processing Machine Category

Rectangle Batch Fryer

Price 175000 INR / Set

Minimum Order Quantity : 1 Set

Capacity : 200400 kg/hr (customized)

Weight : 450 kg

Voltage : 220380 V

Automatic Grade : SemiAutomatic

Circular Batch Fryer

Price 550000 INR / Set

Minimum Order Quantity : 1 Set

Capacity : 50 to 200 kg/hr

Weight : Approx. 350 kg

Voltage : 380 V

Automatic Grade : SemiAutomatic

Tray Oven Dryer Machines

Price 175000 INR / Set

Minimum Order Quantity : 1 Set

Capacity : 100500 kg per batch

Weight : Approx. 3501200 kg

Voltage : 240415 V

Automatic Grade : SemiAutomatic

Mad Angle Cutter

Price 175000 INR / Set

Minimum Order Quantity : 1 Set

Capacity : Heavy Duty (Suitable for Industrial Use)

Weight : Approx. 32 kg

Voltage : 220V

Automatic Grade : SemiAutomatic

|

S. K. Food Equipments Pvt Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry